Triathlon® Cementless

Fixation you can trust.

Triathlon Cementless combines the kinematics of Triathlon with the latest highly porous biologic fixation technology. With over one million cementless knees implanted to date1 and impressive survivorship data2-4 since it was introduced in 2013, Triathlon Cementless has become a trusted solution for surgeons across the globe.

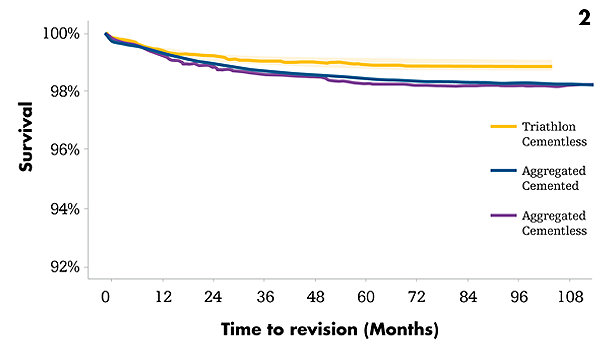

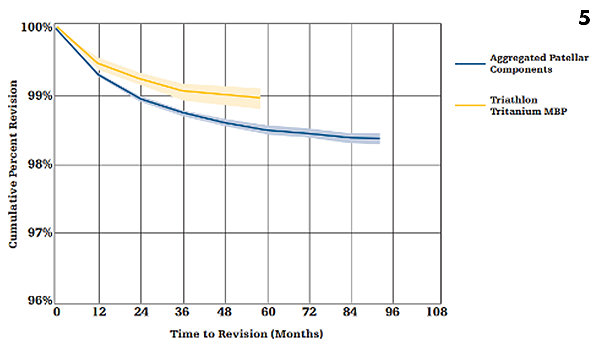

Recent data from the American Joint Replacement Registry (AJRR) across 428 institutions and over 28,000 Triathlon Cementless baseplate patients showed a statistically significant increase in survivorship compared to all cemented and cementless implants at five years.2 The same AJRR data set showed 99% survivorship for the Triathlon Cementless patella at four years.5

Triathlon Cementless

Fixation you can trust.

Trusted results.2

Improved efficiency.6-8

Higher satisfaction.7-9

Triathlon design

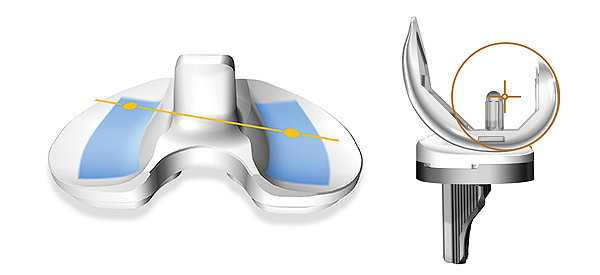

Stable primary fixation of the implant is necessary for biologic fixation.10 The less constrained the design, the less potential there is for stresses generated at the articulating surface to be transferred to the bone-implant interface.11 Triathlon is designed to minimize dynamic stress transfer to the tibial fixation interface by providing minimal resistance to internal and external motion and by locating the bearing sulcus directly over the tibial keel to help reduce sagittal rocking during ambulation.12

Triathlon Cementless Patella

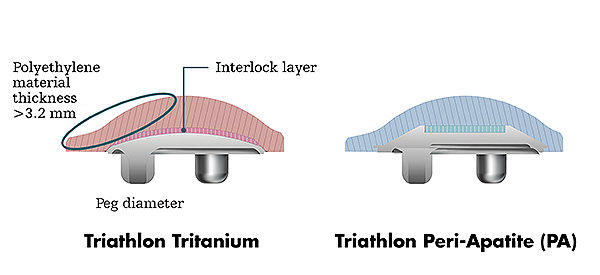

The architecture on the back side of the Triathlon Cementless Patella, combined with a direct compression molding process, is designed to minimize the potential for dissociation.13 Additive manufacturing makes it possible to build a solid barrier layer between the porous surfaces, which allows for a smaller metal backing and greater polyethylene thickness.

Initial stability

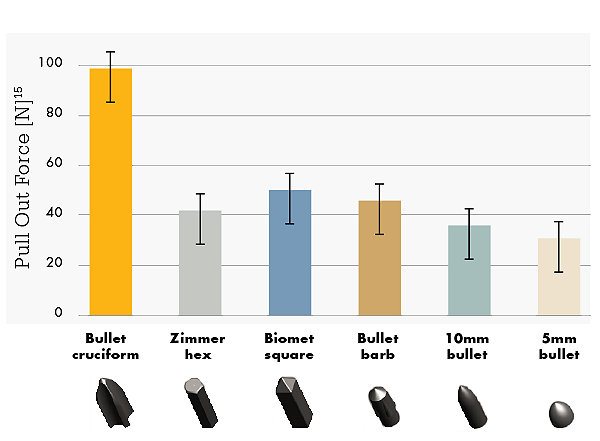

Given the importance of stable primary fixation,10 the underside of the Triathlon Cementless Baseplate was designed to reduce micromotion and liftoff.14 Additive manufacturing technology provided our engineers the ability to think of a design, 3D print it and then test it. Many designs were tested, but none provided greater pull-out force than the Triathlon cruciform peg design.15

SOMA designed

Stryker Orthopaedics Modeling and Analytics (SOMA) is a global database of bone morphology – size, shape, density, stiffness and inner and outer cortical diameters – drawn from diverse populations. SOMA was used to optimize the depth and placement of the Tritanium pegs.16 The Triathlon Cementless Baseplate’s size-specific peg design allows for purchase into denser regions of bone without perforating the cortex.16

Additive manufacturing technology

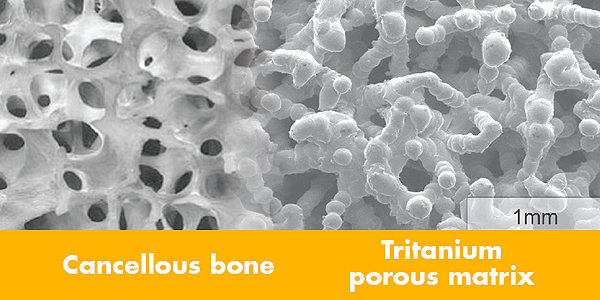

Components for the Triathlon Cementless Baseplate and Patella are additively manufactured using a focused laser beam to sinter numerous layers of titanium powder, which grows the implant structure layer by layer.

With additive manufacturing technology, we can strategically position porous structures in the desired zones of the Triathlon Tritanium Baseplate. Avoiding porous metal in the distal areas may help reduce risks of stress shielding.

Potential savings in time and cost

As the volume of TKA procedures continues to increase, the costs associated with this surgical procedure continue to be an important topic.

Triathlon Cementless allows the potential to reduce operating room time6,7 and save expenses without the use of bone cement and cement accessories.8

Two healthcare economic studies in the U.S. concluded that the actual overall cost of cementless TKA could be offset by shortened operating room time and the lack of need for cement and cementing accessories.8,17*

Several studies have shown using Triathlon Cementless can save 10-15 minutes of OR time6,7 by eliminating the need to mix and apply bone cement.

*Cost savings may differ across regions due to different healthcare systems, treatment plans and associated costs.

Triathlon Cementless TKA demonstrated excellent clinical outcomes in multiple studies with five-year follow-up2-4 and achieved similar functional outcomes as well as pain reduction compared to cemented Triathlon TKA in multiple short- to midterm studies.16-18,19

The mid-term performance of the Triathlon Cementless baseplate and patella was recently investigated using data from the American Joint Replacement Registry (AJRR).2 Triathlon Cementless baseplate cases (N=28,631) from 428 institutions were identified. These cases were compared to all other “Aggregated Cementless” as well as “Aggregated Cemented” knee cases. Implant survivorship free of revision was 98.9% (CI 98.7-99.0), with the Triathlon Tritanium baseplate, 98.3% (CI 97.9-98.6), in the aggregate cementless group and 98.4% (CI 98.4-98.5) in the cemented knee group at 60-month follow-up (p<0.001).2

A similar analysis was performed on the Triathlon Cementless patella using data from AJRR merged with CMS. 28,257 cases from 656 surgeons across 369 sites were identified and included in the analysis. Implant survivorship was 99.0% at four years.5

Mako SmartRobotics™ combines three key components 3D CT-based planning, Accustop haptic technology, and insightful data analytics, into one platform that has shown better outcomes for your total knee, total hip and partial knee patients.19-21

Unlock the powerful combination of Mako SmartRobotics™ and Triathlon Cementless.

Mako’s 3D CT-based planning allows you to see more of your patient’s unique anatomy and accurately plan Triathlon in the coronal, transverse and sagittal planes for each patient.20

To learn more about Mako SmartRobotics™ click here.

Did you know? Triathlon Cementless implants make up over half of the Mako Total Knees implanted in the U.S.1

Contact us

Send us a message to learn more about Triathlon Cementless

This contact form is intended for healthcare professionals. If you’re looking to contact us about patient materials, please go here.

- Stryker Sales Data on File June 12, 2023

- Nam D, Bhowmik-Stoker M, Mahoney OM, Dunbar MJ, Barrack RL. Mid-Term Performance of the First Mass-Produced Three-Dimensional Printed Cementless Tibia in the United States as Reported in the American Joint Replacement Registry. J Arthroplasty. 2023 Jan;38(1):85-89.

- Tarazi JM, Salem HS, Ehiorobo JO, Sodhi N, Mont MA, Harwin SF. Cementless Tritanium Baseplate Total Knee Arthroplasty: Survivorship and Outcomes at 5-Year Minimum Follow-Up. Journal of Knee Surgery. 2020;33(9):862-865. doi:10.1055/s-0040-1712983

- Restrepo S, Smith EB, Hozack WJ. Excellent mid-term follow-up for a new 3D-printed cementless total knee arthroplasty. Bone Joint J. 2021;103(6):32-37. doi:10.1302/0301-620X.103B6

- Bhowmik-Stoker, M., Nevelos, J., Barrack, R., Mont, M, Mahoney, M., Dunbar, M and Nam, D. Mid-term Performance of 28,257 Metal-Backed Patellae from the American Joint Replacement Registry (AJRR). [Poster session]. 2021 AAHKS Annual Meeting, 11-14 November 2021, Dallas, TX.

- Nam, D, et al. Cemented Versus Cementless Total Knee Arthroplasty of the Same Modern Design: A Prospective, Randomized Trial. The Journal of Bone and Joint Surgery 101(13):p 1185-1192, July 3, 2019. | DOI: 10.2106/JBJS.18.01162

- Sharpe, K., Robinson, K., Cohen, R., Barnett TM., Rastogi, A., Masini, M. Does Implant Fixation Affect Early Return to Function Following Primary Total Knee Arthroplasty. ISTA 2018. London, UK.

- Lawrie CM, Schwabe M, Pierce A, Nunley RM, Barrack RL. The cost of implanting a cemented versus cementless total knee arthroplasty. Bone Joint J. 2019 Jul;101-B(7_Supple_C):61-63. doi: 10.1302/0301-620X.101B7.BJJ-2018-1470.R1. PMID: 31256655.

- Hannon CP, Salih R, Barrack RL, Nunley RM. Cementless Versus Cemented Total Knee Arthroplasty: Concise Midterm Results of a Prospective Randomized Controlled Trial. JBJS. 2023 Jun 22:10-2106.

- Nilsson et al. Evaluation of micromotion in cemented vs uncemented knee arthroplasty in osteoarthritis and rheumatoid arthritis. Randomized study using Roentgen stereophotogrammetric analysis. J Arthroplasty. 1991;6(3):265-278. doi:10.1016/s0883-5403(06)80174-9

- Bhimji et al. Kester M, Schmalzried T. Rotational constraint of posterior-stabilized total knee prostheses. J Knee Surg. 2008;21(4):315-319. doi:10.1055/s-0030-1247838

- Harwin et al. Excellent fixation achieved with cementless posteriorly stabilized total knee arthroplasty. J Arthroplasty. 2013;28(1):7-13. doi:10.1016/j.arth.2012.06.006

- Stryker technical report: Report number RD-12-044. Tritanium patella static tensile bond strength of poly/metal interface. 2013.

- Bhimji et al. Micromotion of cementless tibial baseplates: keels with adjuvant pegs offer more stability than pegs alone. J Arthroplasty. 2014;29(7):1503-1506. doi:10.1016/j.arth.2014.02.016

- Stryker technical report: Report number RD-13-107. Effect of geometry on peg fixation strength. 2013.

- Stryker tolerance analysis: Project number 92911. Triumph Tritanium Knee. D02521-1; 2013.

- Yayac et al. The use of cementless components does not significantly increase procedural costs in total knee arthroplasty. J Arthroplasty. 2020;35(2): 407-412.

- Harwin, SF. et al. Outcomes of Newer Generation Cementless Total Knee Arthroplasty: Beaded Periapatite-Coated vs Highly Porous Titanium-Coated Implant. J Arthroplasty. 2017 Jul;32(7):2156-2160. doi: 10.1016/j.arth.2017.01.044. Epub 2017 Feb 3

- Illgen, R, Bukowski, B, Abiola, R, Anderson, P, Chughtai, M, Khlopas, A, Mont, M. Robotic-assisted total hip arthroplasty: Outcomes at minimum two year follow up. Surgical Technology International. 2017 July 25; 30:365-372.

- Kayani B, Konan S, Tahmassebi J, Pietrzak JRT, Haddad FS. Robotic-arm assisted total knee arthroplasty is associated with improved early functional recovery and reduced time to hospital discharge compared with conventional jig-based total knee arthroplasty: a prospective cohort study. The Bone and Joint Journal. 2018;100-B:930-7.

- Kleeblad LJ, Borus T, Coon T, Dounchis J, Nguyen J, Pearle A. Midterm survivorship and patient satisfaction of robotic-arm assisted medial unicompartmental knee arthroplasty: a multicenter study. The Journal of Arthroplasty. 2018:1-8.

JR-TRIT-SYK-769601