Ireland team swiftly produces face shields to meet local hospital needs

17-Apr-2020

Like many countries, Ireland has experienced a shortage of personal protective equipment (PPE) for their front-line workers. When Ireland’s public health services organisation, Health Services Executive (HSE), asked us for help – with a specific request for face shields – our local team sprung to action.

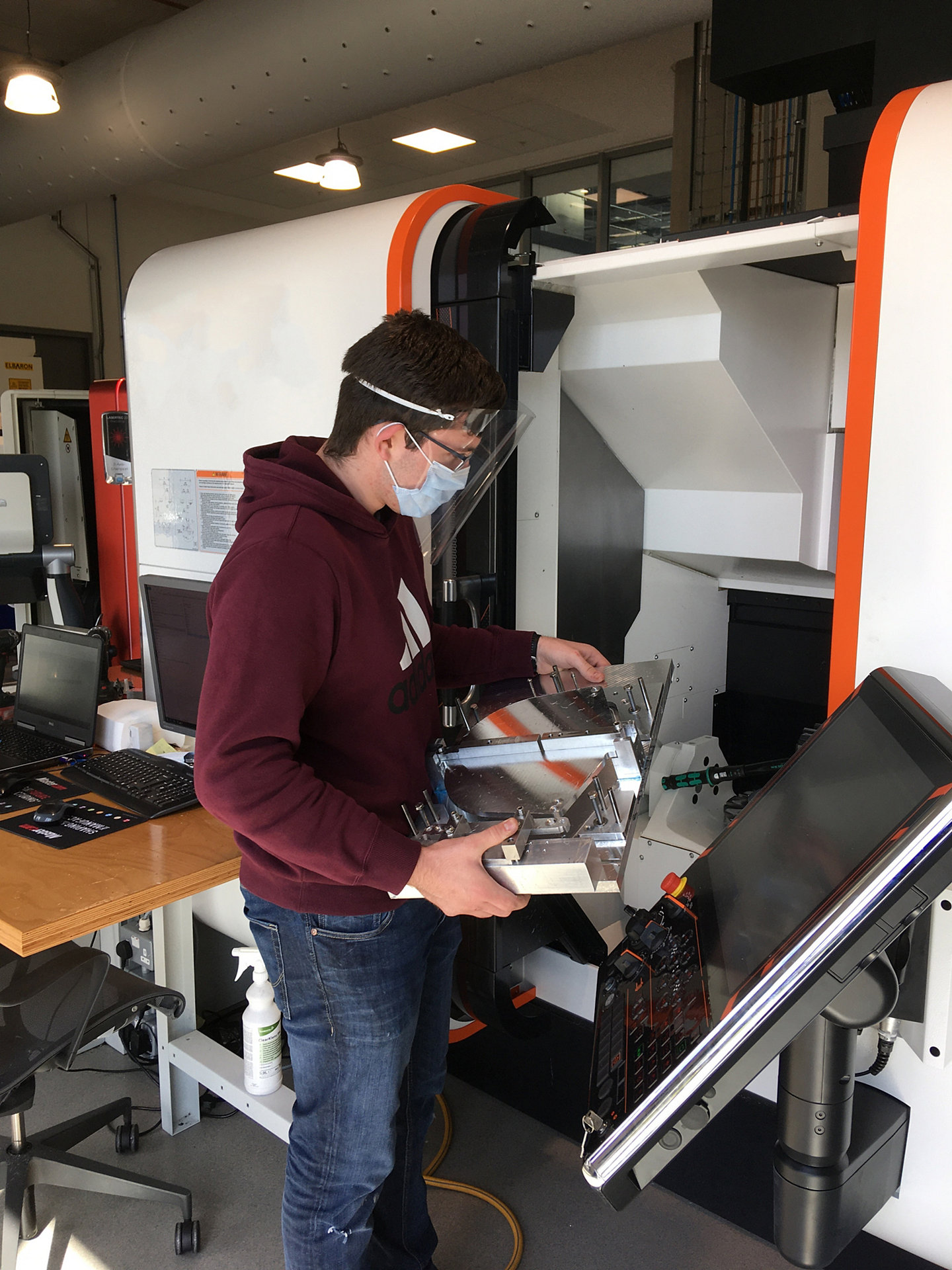

At our Innovation Centre in Cork, the team began the development of a new face shield prototype. Within a week, they had partnered with our facility in Tullagreen to bring the project from request through initial order completion.

To accomplish this, the team set up a supply chain, built prototypes – including five design iterations with input from the customer – designed packaging, secured European compliance and developed a manufacturing process and production line.

“We’ve successfully manufactured 7,000 face shields to meet the need of our local hospitals and nursing homes to date,” said Kevin Manley, Senior Director, Global Research and Engineering Services. “We have 10,000 shields on order for Cork University Hospital and have been contacted by more hospital groups in Ireland asking for our support with a further 6,000 on order to support their immediate needs. We are eager to help alleviate the strain felt by our customers through the development of these new face shields to help protect their front-line workers.”

Looking forward, the team hopes to replicate the manufacturing of the new face shields in other European countries and India, to produce up to 450,000 per month by summer.

Our customers and their patients are at the heart of everything we do. And the swift work by our team in Ireland to act with urgency and meet the immediate need for PPE at their local hospitals is an example of how we deliver on that promise.