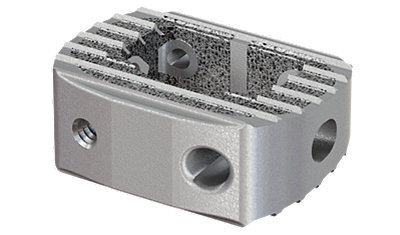

Tritanium C

Anterior Cervical Cage

A hollow implant that consists of a unique configuration of both solid and porous structures built using AMagine Technology, our proprietary approach to implant creation using additive manufacturing

Tritanium C Anterior Cervical Cage

This cage is available in a variety of footprints, heights and lordotic angles to accommodate various patient anatomies. It features a large, open graft window to maximize bone graft volume and lateral windows to reduce stiffness of the cage and aid in visualization of fusion. A threaded inserter connection promotes rigid connectivity and control during insertion.

Our proprietary Tritanium In-Growth Technology, used to build the Tritanium PL and C Cages, was designed for bone in-growth and biological fixation1

Unique porous structure of Tritanium technology is designed to create a favorable environment for cell attachment and proliferation2,3 and may be able to wick or retain fluid when compared to traditional titanium material4

Porous structures feature randomized pore shape and sizing that are designed to mimic cancellous bone3,5

Interconnected pore structure from endplate to endplate3

Compared to other available materials for ACDF, offers no risk of donor infection, no donor lot variability, no special tracking or distribution and no special preparation (i.e., soaking)

Created to allow imaging6

Shaped for stability7,8

Developed to minimize subsidence9

Empowered by AMagine Technology – our proprietary approach to implant creation using additive manufacturing

References:

- PROJ 43909 | Tritanium technology claim support memo

- RD0000053710 | Tritanium cell infiltration and attachment experiment

- Karageorgiou V, Kaplan D. Porosity of 3D biomaterial scaffolds and osteogenesis. Biomaterials 2005;26:5474–91

- RD0000050927 | Tritanium material capillary evaluation

- DHF0000053171 | Tritanium C 510(k) Physical Testing Report

- PROJ0000054459 | Tritanium C implant imaging marketing memo

- PROJ0000054458 | Tritanium C insertion and expulsion marketing memo

- PROJ44960 | Coefficient of friction memo

- PROJ0000054457 | Tritanium C subsidence marketing memo