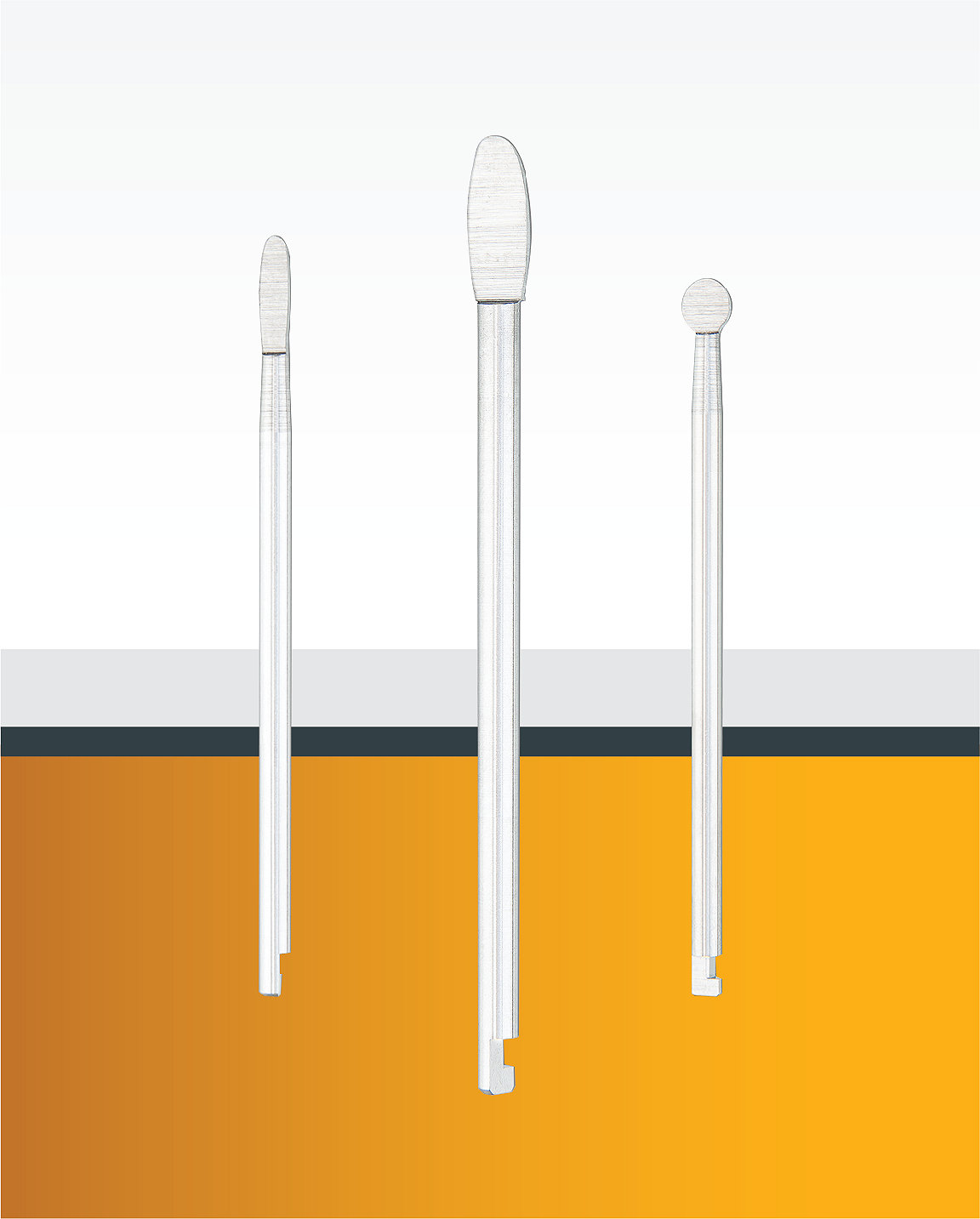

Performance Series Blades

The use of Stryker Heavy Duty saws with Performance Series blades provide an excellent combination while maximising cut-efficiency, cut accuracy and control.

Performance Series Blades

Premium design. Proven results.

Performance Series 6125-127-90 blades

Performance Series

____________________________________________

Reliable heavy duty cutting technology

Designed for heavy duty cutting applications

- Beveled Edges

- Stabile Construction

- Patented Tooth Design

- Constant Blade Thickness

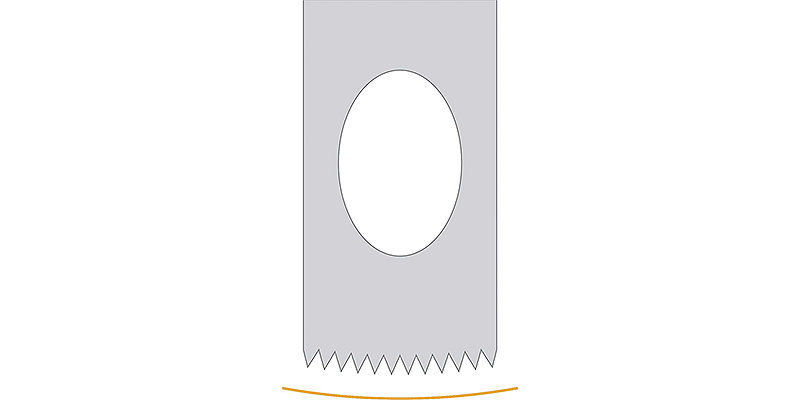

- Beveled Edges

______________________________________________________________

Beveled edges are intended to reduce the likelihood of soft tissue damage as compared to non-beveled blades1

They also aid in the reduction of wear debris within the cutting block2

This is particularly evident with single use cutting blocks2

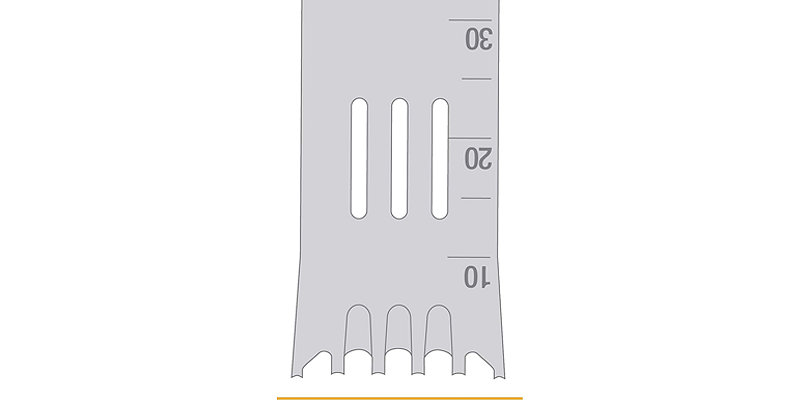

- Stability

______________________________________________________________

Concave tooth design stabilizes the blade by engaging fewer teeth at on time

This improves overall control of the saw3

- Patented Tooth Design

______________________________________________________________

Inner teeth feed bone chips into chip clearance area allowing for a more efficient cut

- Accuracy

______________________________________________________________

Constant blade thickness improves overall cut accuracy by having optimal fit in the cutting block. This reduces blade skive and increases blade stiffness by 30%4

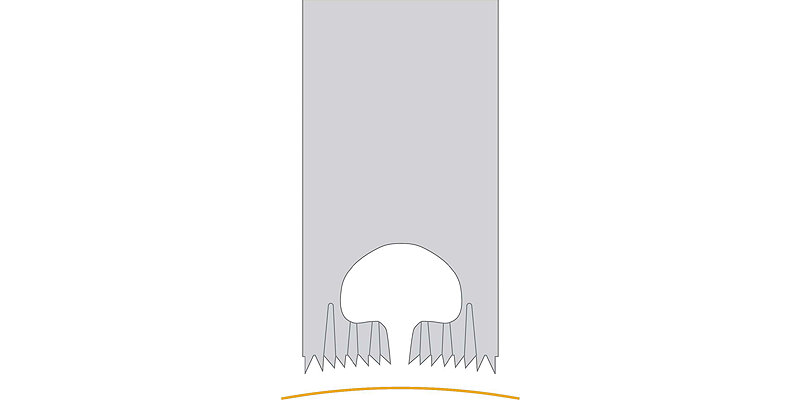

Convex

Least Stable

All teeth engage bone at the same time. This causes the tendency for the blade to kick out during the cut.

Straight

Better control characteristic

Progressive engagement of cutting teeth. Reduces cutting force and kick out. Allows user better control of saw. Improved control allows faster cutting.

Concave

Most Stable

Concave shape creates a cutting face that keeps blade centered at all times and allows the smoothest cut possible. Fewer teeth engaged means blade does not grab or kick.

"Smarter technologies help allow patients to experience a higher quality of life, for a longer duration."

- Denis O'Sullivan, Stryker

1. Reference TrS1805.051621 for soft tissue protection. Rounded edges added to blades to minimise tissue damage during procedures. 2. Reduction of wear debris covered e.g. F6113.062448, F6118.062414, F6125.062445, S1805.081088, S1805.080285 3. The stability claim is covered by ‘Whip’ tests such as F6113.062447, S1805.070630, F6118.062416, F6125.062444, S1805.081088 4. Increased stiffness for the majority of parts by 30% based on design calculation

SMACC 2021-28368 / SMACC 2021-28365