________________________________________

Our world’s resources are limited. That’s why we’re maximising what we have.

Our teams are proactively working to reduce both what we use and what we leave behind. We’re tracking our progress and installing global reporting systems, setting and making progress towards our goals and reducing our use of resources across the company.

________________________________________

Climate and the environment

Climate change is already affecting the air we breathe and the food we eat, and it is exacerbating extreme weather affecting our communities. As a healthcare company, we know that we make choices that affect the health of the planet, and ultimately, human health. That's why we are continually measuring our carbon emissions and have set reduction goals to reduce our impact. In 2023 we announced that we reduced our carbon emissions by over 20%. Our current goals are:

- Power all facilities with 100 per cent renewable electricity by 2027

- Make all Stryker facilities carbon neutral (scopes 1 and 2) by 2030

110+

energy-reduction projects implemented at 30 Stryker sites

19,000

metric tons of CO2 reduced from projects since 2019

8%

additional annual reduction in emissions through projects implemented in 2022

1,500+

homes could be powered with the reduction in energy from implemented projects since 2019

To achieve these ambitious climate goals, our strategy includes increasing energy efficiency throughout the organisation and utilising renewable energy.

Energy efficiency

Continual improvements in energy efficiency will contribute approximately 25 per cent to our carbon-neutral journey by 2030. Over the past few years, we have committed $20 million in capital investments to reduce emissions. Highlights of projects we have invested in include:

- Arroyo, Puerto Rico: combined heat and power is expected to reduce the facility’s emissions by over 4,000 metric tons and save more than US $1 million annually in electricity costs, plus allowing the plant to continue operating in the event of power outages.

- Mahwah, New Jersey: new compressed air systems, chiller systems and improved controls, are expected to reduce annual emissions by over 1,800 metric tons.

- Cary, Illinois, USA: saved more than 260 metric tons of carbon annually by replacing lighting in its warehouse and car park with LEDs.

- Kalamazoo, Michigan facilities will benefit from an upgraded building management system and boiler plant and reduce carbon emissions by over 750 metric tons per year.

- Selzach, Switzerland facility upgraded to a biomass heating system that will eliminate approximately 63,000 litres of heating oil, resulting in savings of over 150 metric tons of carbon annually

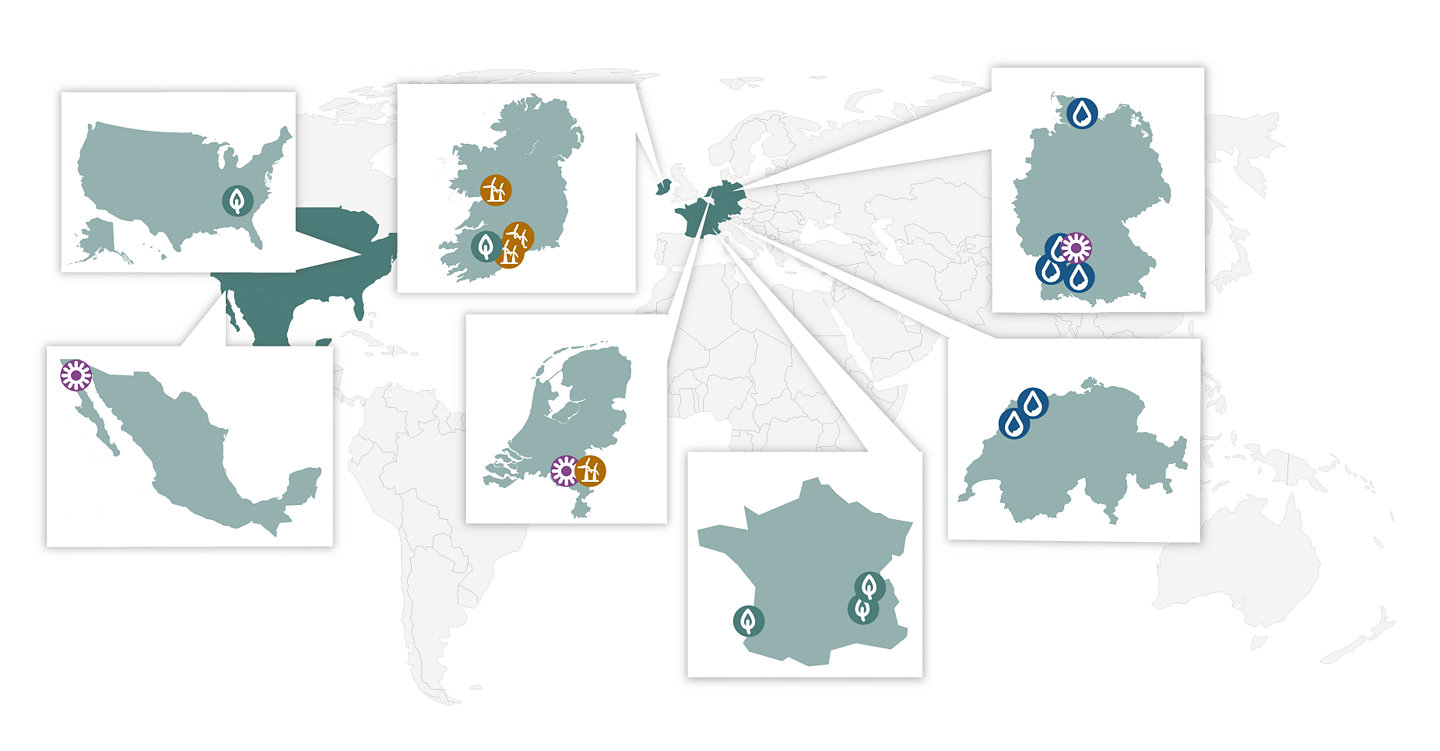

Renewable energy

Our pathway to carbon-neutrality depends on transitioning from fossil fuel-based to renewable electricity. Currently, 18 Stryker sites are powered by renewable energy, covering 33 per cent of our global electricity needs. In Europe, we procure 88 per cent of our electricity from renewable sources. In 2022, we announced a new goal for our global sites to be powered by 100 per cent renewable electricity by 2027. This electricity will come from a combination of wind, solar, hydroelectric and other sources. Stryker partnered with global clean energy leader Ørsted and with Schneider Electric, a global leader in sustainability and renewable energy procurement, to establish our first long-term renewable power purchase agreement. The Sunflower Wind Farm, operated by Ørsted, is a 200 MW wind project. We expect that this 12-year agreement will generate enough wind power to supply 75 per cent of our current electricity needs in North America. Construction on the wind turbines commenced in late 2022, and the project is expected to be online by 2024.

Hydroelectric procurement

Freiburg, Germany

Kiel, Germany

Stetten, Germany

Tutlingen, Germany

La Chaux-de-Fonds, Switzerland

Selzach, Switzerland

Onsite solar

Freiburg, Germany

Venlo, Netherlands

Tijuana, Mexico

Wind procurement

Cork, Ireland

Limerick, Ireland

Venlo, Netherlands

Renewable procurement mix

Cestas, France

Grenoble, France

Montbonnot, France

Macroom, Ireland

Memphis, TN, United States

Certifying our facilities

We recognise that our offices and manufacturing facilities have an impact on the communities in which they are located and the world's health. By working with accrediting organisations to evaluate and certify the environmental impact and sustainability of our buildings, we commit to protecting natural resources and supporting our employees and their communities. We currently have over a dozen global sites certified to the ISO14001 global environmental standard. The following Stryker locations have been certified by Leadership in Energy and Environmental Design (LEED), a green building rating system; and Building Research Establishment Environmental Assessment Method (BREEAM), a sustainability performance rating system:

LEED: Hong Kong, China; Suzhou, China; Freiburg, Germany; Arroyo, Puerto Rico, US; Cary, IL, US; Flower Mound, TX, US; Fort Lauderdale, FL, US; Mahwah, NJ, US; Portage, MI, US (3); San Jose, CA, US; Tijuana, Mexico, Waterdown, ON, Canada

BREEAM: Newbury, Berkshire, UK; Venlo, Netherlands; Warsaw, Poland

Triathlon cementless tibial baseplate created using additive manufacturing

Products that do more with less

________________________________________

Manufacturing our products requires materials, energy and water, and often generates waste as a by-product. Stryker recognises the need to focus on sustainable design as a strategic priority and integrate sustainability into our products and packaging. We have made progress in multiple areas:

- Conducting lifecycle assessments (LCAs) to learn about our impacts and areas for improvement

- Optimising our manufacturing process to generate less waste

- Collecting and reprocessing single-use devices so they can be used again

- Using additive manufacturing, which results in fewer emissions and less waste

- Investing in alternative sterilisation methods

- Designing products that help customers reduce medical waste in hospitals

Stryker’s Sustainability Solutions

The lifespan of many medical products is relatively short; many devices are used only once, leading to thousands of tons of materials sent to landfills each year. As the leading provider of reprocessing in the global healthcare market, Stryker’s Sustainability Solutions business unit is reducing our industry’s impact during manufacturing, use and end of life.

Sustainability Solutions helps reduce healthcare industry waste by reprocessing medical devices that would otherwise be disposed of after a single use, extending the life of these products and reducing material consumption. Sustainability Solutions collects and reprocesses devices spanning thousands of SKUs. Over the last five years, more than 3,000 customers saved approximately $1 billion through reprocessing programmes and diverted over 25 million pounds of waste from landfills.

________________________________________

We recognise that partnership is a key component of our sustainability strategy; sharing our story and learning from others. We are active members in the following organisations:

Additive Green Manufacturing Trade Association

Association of Medical Device Reprocessors

Clean Energy Buyers Association (CEBA)

Healthcare Plastics Recycling Council (HPRC)

Ireland’s Business in the Community Low Carbon Pledge

National Academy of Medicine’s Action Collaborative on Decarbonising the US Health Care Sector

*Data validated September 2021

COMM-GSNPS-SYK-764140